Weighing Precision and Efficiency: Navigating the Automatic Weighchecker Market

In the dynamic landscape of industrial processes, precision and efficiency are paramount. The Automatic Weighchecker Market, a pivotal player in this pursuit, is flourishing with a Compound Annual Growth Rate (CAGR) of 7.5%, expected to culminate in a global valuation of $2.1 billion by the end of 2025. This significant growth is indicative of the industry’s importance in optimizing various sectors of manufacturing and production.

According to Reports and Insights analysis, the global automatic weighchecker market was US$ 109.5 Billion in 2022.

“Ready to take your business to the next level? Start with our free sample report download.”- https://www.reportsandinsights.com/sample-request/1987

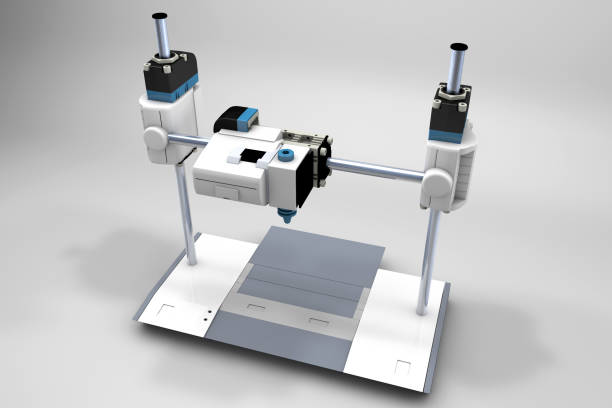

Automatic Weighchecker: A Precision Instrument

At the heart of this burgeoning market are automatic weighcheckers, sophisticated instruments designed to ensure the accuracy and consistency of weight measurements in various industries. These devices have found applications across a spectrum of sectors, including food and beverage, pharmaceuticals, logistics, and manufacturing. The primary function of an automatic weigher is to precisely measure the weight of products, packages, or ingredients and verify their compliance with predetermined standards. This verification process helps maintain product quality, regulatory compliance, and operational efficiency.

Company List:

- Mettler-Toledo International Inc.

- Ishida Co., Ltd.

- Minebea Intec

- A&D Company, Limited

- Bizerba SE & Co. KG

- Anritsu Corporation

- Loma Systems

- Yamato Scale Co., Ltd.

- Thermo Fisher Scientific Inc.

- OCS Checkweighers GmbH

- Precia Molen

- Multivac Group

- WIPOTEC-OCS GmbH

- CI Precision Ltd.

- Flintec Group AB

“Ready to take your business to the next level? Don’t miss out on this opportunity BUY NOW”- https://www.reportsandinsights.com/buy-now/1987

Segmentation, Drivers, Restraints, and Opportunities

The Automatic Weighchecker Market can be segmented by product type, application, and geography. Product types encompass dynamic checkweighers, in-motion weighers, and static weighers, each tailored to specific operational requirements. Dynamic checkweighers, for instance, are adept at inspecting products on a conveyor belt, ensuring that they meet the desired weight criteria, while static weighers are utilized for batch processes, ensuring precision in material mixing.

The driving forces behind the growth of this market are multifaceted. Regulatory compliance in industries such as pharmaceuticals and food necessitates strict adherence to weight standards, propelling the adoption of automatic weighers. Moreover, the relentless pursuit of operational efficiency and quality assurance in manufacturing bolsters the demand for these devices. However, challenges like initial investment costs and the need for specialized technical expertise might act as restraints.

Opportunities abound in the Automatic Weighchecker Market, particularly in the context of Industry 4.0. The integration of automation and data analytics is revolutionizing weighchecker technology. Real-time data analysis not only enhances precision but also offers valuable insights for process optimization. Furthermore, the growing demand for eco-friendly packaging materials opens doors for innovation in weighchecking technology, as manufacturers seek to reduce waste and minimize environmental impact.

Understanding Automatic Weighers: Benefits and Types

An automatic weigher is a precision instrument that measures the weight of objects with a high degree of accuracy. These instruments offer several benefits to industries:

Accuracy: Automatic weighers are highly accurate, ensuring that products meet weight specifications consistently.

Efficiency: They operate at high speeds, making them suitable for use in fast-paced production lines.

Data Collection: Many automatic weighers come equipped with data collection and reporting features, enabling quality control and process optimization.

Cost Savings: By reducing product giveaway and ensuring compliance, automatic weighers can lead to significant cost savings over time.

There are different types of automatic weighers, including:

Dynamic Checkweighers: These weigh products as they move along a conveyor belt, providing real-time feedback on weight accuracy.

In-Motion Weighers: Similar to dynamic checkweighers, these devices are designed for high-speed, continuous weighing applications.

Static Weighers: These weighers are used for batch processes, where products or ingredients are weighed before or after a specific manufacturing step.

As for the cost, it varies depending on the type and complexity of the automatic weigher. Entry-level models can start at a few thousand dollars, while high-end, fully automated systems can cost tens of thousands of dollars.

Choosing the Right Automatic Weigher

Selecting the right automatic weigher depends on various factors, including the type of products being weighed, the required accuracy, and the production volume. Considerations should include:

Accuracy Requirements: Determine the level of precision needed for your application.

Product Size and Weight Range: Ensure the weigher can accommodate the size and weight of your products.

Production Speed: Choose a weigher that can keep up with your production line’s speed.

Integration: Consider how the weigher will integrate with your existing systems and whether it offers data connectivity features.

Maintenance and Support: Evaluate the availability of maintenance and technical support for your chosen weigher.

Purchasing an Automatic Weigher

Automatic weighers can be purchased from specialized manufacturers and suppliers. It’s crucial to research reputable companies known for their quality and customer support. Online marketplaces and industry-specific trade shows are also valuable resources for discovering the latest advancements in weighchecker technology.

“Ready to take your business to the next level? Start with our free sample report download.”- https://www.reportsandinsights.com/sample-request/1987

Latest Developments in the Automatic Weighchecker Industry

The Automatic Weighchecker industry is witnessing rapid advancements to meet the demands of modern manufacturing. Recent developments include:

Artificial Intelligence (AI) Integration: Many automatic weighers now incorporate AI algorithms for improved accuracy and predictive maintenance.

Industry 4.0 Integration: Weighcheckers are becoming integral components of smart factories, enabling real-time data analysis and automated decision-making.

Improved User Interfaces: User-friendly interfaces and touch-screen displays make these machines more accessible to operators.

Enhanced Data Analytics: Automatic weighers are providing more detailed data on weight variations, allowing manufacturers to pinpoint and address production issues quickly.

Sustainability Focus: Weighchecker manufacturers are exploring eco-friendly materials and design principles to reduce the environmental impact of their products.

In conclusion, the Automatic Weighchecker Market is evolving rapidly, driven by the need for precision, quality assurance, and operational efficiency across various industries. As technology continues to advance, automatic weighers are poised to play an even more integral role in modern manufacturing, offering benefits that extend far beyond accurate weight measurement. Whether in the food industry, pharmaceuticals, or logistics, these instruments are shaping the future of quality control and production optimization.

“Ready to take your business to the next level? Don’t miss out on this opportunity BUY NOW”- https://www.reportsandinsights.com/buy-now/1987

About Reports and Insights:

Reports and Insights is one of the leading market research companies which offers syndicate and consulting research around the globe. At Reports and Insights, we adhere to the client needs and regularly ponder to bring out more valuable and real outcomes for our customers. We are equipped with strategically enhanced group of researchers and analysts that redefines and stabilizes the business polarity in different categorical dimensions of the market.

Contact Us

Reports and Insights

Tel: +1-(718)-312-8686

For Sales Query: sales@reportsandinsights.com

For New Topics & Other Info: info@reportsandinsights.com

Website: https://reportsandinsights.com