Navigating the Growth Wave: Selective Soldering System Market Trends

Introduction

In an era where electronics and technology continue to shape our world, the need for precision and efficiency in manufacturing processes has never been greater. The Selective Soldering System Market, a vital component of the electronics manufacturing industry, is making significant strides in providing cutting-edge solutions. This article delves into the dynamic landscape of Selective Soldering Systems, revealing market trends, sales insights, and the latest industry developments that are set to impact the future.

According to Reports and Insights analysis, the global selective soldering system market was US$ 166.3 Million in 2022.

Furthermore, the selective soldering system market to register a CAGR of 5.78% which is expected to result in a market forecast value for 2031 of US$ 275.76 Mn.

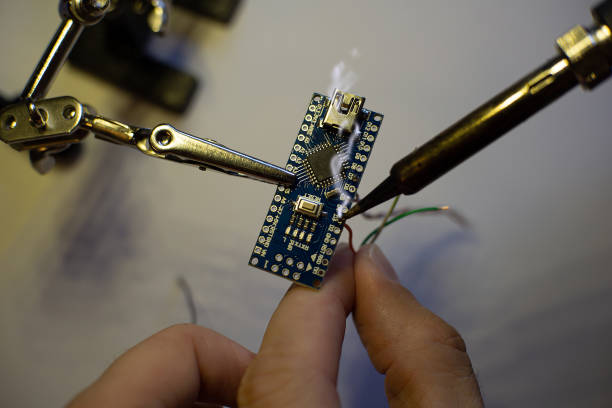

A selective soldering system is a specialized machine used in electronics manufacturing to solder specific components on a Printed Circuit Board (PCB). Unlike traditional wave soldering, which immerses the entire PCB in molten solder, selective soldering selectively applies solder to specific areas. This method offers several benefits, including precise control over solder placement, reduced heat stress on sensitive components, and the ability to solder complex or heat-sensitive assemblies.

There are different types of selective soldering systems available in the market, such as standalone systems, inline systems, and robotic systems. Standalone systems are compact and versatile, suitable for low to medium volume production. Inline systems integrate with the production line for high-volume manufacturing, while robotic systems use robotic arms for increased flexibility and automation. Each type has its own advantages and can be chosen based on production requirements.

Ready to take your business to the next level? Start with our free sample report download.”-@ https://www.reportsandinsights.com/sample-request/1895

Selective Soldering System Market Overview

The Selective Soldering System Market is a key player in the realm of electronics manufacturing. These systems offer precise and automated soldering solutions, catering to the intricacies of modern Printed Circuit Board (PCB) assembly. According to Reports and Insights analysis, the Selective Soldering System market is projected to achieve a noteworthy Compound Annual Growth Rate (CAGR) of 5.78% during the forecast period from 2023 to 2031. This impressive growth signifies the critical role Selective Soldering Systems play in the evolving electronics manufacturing landscape.

Selective Soldering System: Precision at Its Best

Selective Soldering Systems have emerged as the preferred choice for various manufacturing processes due to their exceptional precision and efficiency. This equipment allows manufacturers to target specific areas of a PCB for soldering, ensuring accuracy and avoiding damage to adjacent components. Whether it’s the soldering of intricate through-hole components or surface mount technology (SMT) soldering, Selective Soldering Systems provide an ideal solution.

The Applications of Selective Soldering Systems

The Selective Soldering System’s flexibility and precision make it suitable for a wide range of applications in electronics manufacturing. Here are some of the primary areas where these systems excel:

- High-Precision Soldering: Selective Soldering Systems excel in applications demanding precision soldering, where even the smallest error can lead to electronic malfunction.

- PCB Soldering: The heart of electronic devices, PCBs, rely on Selective Soldering Systems to establish the critical connections that power our gadgets.

- Lead-free Soldering: As the industry transitions towards environmentally friendly practices, Selective Soldering Systems are instrumental in lead-free soldering processes.

- Soldering in SMT Manufacturing: SMT technology demands precision and efficiency, and Selective Soldering Systems provide an ideal solution for this manufacturing process.

- Flux Application: Accurate flux application is crucial for soldering quality, and Selective Soldering Systems ensure the right amount is applied precisely where it’s needed.

Segmentation, Drivers, Restraints, and Opportunities

Segmentation: The Selective Soldering System Market can be segmented based on various factors, including the type of system (automated or robotic), end-users (electronics manufacturing, automotive, aerospace, etc.), and geographic regions.

Drivers: The market is driven by increasing demand for electronics, the shift toward lead-free soldering, and the need for high-precision soldering systems to ensure product quality.

Restraints: Challenges such as the initial cost of equipment and the need for skilled operators may restrain market growth.

Opportunities: Emerging trends like Industry 4.0, which involve automation and data exchange in manufacturing technologies, present significant opportunities for the Selective Soldering System Market.

Latest Developments in the Industry

The Selective Soldering System Market is dynamic and constantly evolving. Recent developments in the industry include:

- Industry 4.0 Integration: Manufacturers are increasingly integrating Selective Soldering Systems into their Industry 4.0 initiatives for improved automation and data-driven decision-making.

- Enhanced Software: Newer software solutions offer better control, programming, and optimization of Selective Soldering Systems, reducing setup times and enhancing efficiency.

- Energy Efficiency: Energy-efficient Selective Soldering Systems are being developed to meet the growing demand for sustainability.

Top Players in the Selective Soldering System Market

Leading companies are driving innovation and competition in the Selective Soldering System Market. Some of the top players include:

- ACE Production Technologies

- Pillarhouse International Ltd.

- Ersa GmbH

- JUKI Automation Systems

- Nordson SELECT

- Seika Machinery, Inc.

- Solderstar Ltd.

- Tamura Corporation

- Senju Metal Industry Co., Ltd.

- RPS Automation LLC

Key Market Insights

- Competition by Manufacturers: Intense competition among manufacturers is leading to innovations and advancements in Selective Soldering Systems.

- New Additions in 2023: The market is witnessing new product additions and technological enhancements to meet the changing demands of the electronics manufacturing industry.

- Most Important Types: Robotic Selective Soldering Systems and Automated Selective Soldering Systems are among the most important types driving market growth.

- Key Benefits of Selective Soldering System Market: Improved solder joint quality, reduced defects, enhanced precision, and compliance with lead-free soldering regulations are key benefits.

- Selective Soldering System Forecast: The market is set to expand further, with increased demand for advanced electronics and the transition to lead-free soldering.

- Reason to Buy the Report and Driving Factors: Industry stakeholders can benefit from market reports to stay updated on trends, opportunities, and emerging players. The driving factors include the growing electronics industry and the need for efficient soldering solutions.

Ready to take your business to the next level? Start with our free sample report download.”-@ https://www.reportsandinsights.com/sample-request/1895

Frequently Asked Questions

- What is Selective Soldering? Selective Soldering is a soldering process that precisely targets specific areas on a PCB for solder application, ensuring high-quality connections and avoiding damage to nearby components.

- What are the key trends in the Selective Soldering System Market? Key trends include the integration of Industry 4.0, enhanced software solutions, and a focus on energy efficiency.

- Why is lead-free soldering important? Lead-free soldering is crucial for environmental and health reasons, as it eliminates the use of toxic lead in electronic components.

Regional Segmentation

The Selective Soldering System Market exhibits regional variations based on the concentration of electronics manufacturing. Major regions for Selective Soldering Systems include North America, Europe, Asia-Pacific, and emerging markets in South America and Africa.

In conclusion, the Selective Soldering System Market is poised for substantial growth, driven by increasing demands for electronics and the need for precise and efficient soldering solutions. With innovation and automation on the rise, the industry’s future looks promising, and it is vital for businesses to stay informed about the latest trends and developments in this dynamic sector.

Enquire before purchasing this report —@ https://www.reportsandinsights.com/talk-to-consultant/1895

About Reports and Insights:

Reports and Insights is one of the leading market research companies which offers syndicate and consulting research around the globe. At Reports and Insights, we adhere to the client needs and regularly ponder to bring out more valuable and real outcomes for our customers. We are equipped with strategically enhanced group of researchers and analysts that redefines and stabilizes the business polarity in different categorical dimensions of the market.

Contact Us

Reports and Insights

Tel: +1 347 748 1518

For Sales Query: sales@reportsandinsights.com

For New Topics & Other Info: info@reportsandinsights.com

Website: https://reportsandinsights.com