According to ChemAnalyst report, “Global Polymer concrete Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, Technology, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, global polymer concrete market has shown tremendous growth in the past five years and is anticipated to achieve a CAGR of 6.54% during the forecast period. Rapid urbanization backed by the increasing need for chemical and environment resistant construction material and adoption of new construction techniques is expected to drive the demand of polymer concrete for the forecast period. In addition, continuous revamping of infrastructure in disaster prone countries like Japan, South Korea is expected to push the demand further during the forecast period.

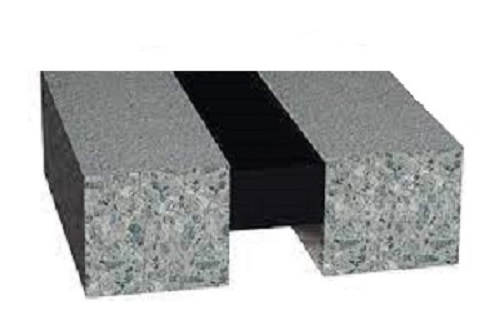

Polymer concrete is a type of concrete which contains polymers instead of lime cement as binder. Polymer concrete is a typical composite material where the constituents such as hardening agent, gravel, sand, filter, quartz powder etc. are bind in the polymer matrix of the composite material. Based on polymer type, polymer concrete can be classified into epoxy, vinyl ester, polyester, methyl methacrylate, and others. Polymer concrete offers several advantages over conventional concrete and has properties such as moisture resistivity, adhesion, thermal stability, mechanical strength, and heat resistance. Due to these properties, polymer concrete finds application in various areas such as asphalt pavement, building and maintenance, industrial tanks, drainage systems, and others.

Read Full Report Here: https://www.chemanalyst.com/industry-report/polymer-concrete-market-550

Polymer concrete is a material which has very high mechanical strength and apart from mechanical strength it has environment and chemical resistance and lightweight as compared to conventional concrete. This paves the way for polymer concrete to find application in almost every area requiring high environment and chemical strength, and light weight. Therefore, they find application in asphalt pavement, building and maintenance, industrial tanks, drainage systems. Out of the following application areas, asphalt pavement holds the major share of the global polymer concrete market. industrial tanks which require high chemical resistance are also another area holding major share of polymer concrete market. Increasing urbanization backed by increasing construction needs from the above sectors is going to support demand rise for polymer concrete for the forecast period.

Polymer concrete consists of polymer matrix and other components such as hardening agent, gravel, sand, filter, quartz powder etc. hence its price is directly linked to the fluctuations in the price of polymers such as epoxy, vinyl ester, polyester, methyl methacrylate, and others. In the first half of FY20 sudden outbreak of novel coronavirus followed by fall in in the demand of construction rendered a major downfall in the global polymer concrete demand hence the prices remained low for polymer concrete during the coronavirus pandemic. Demand has picked up in the recent quarters and is projected to grow due to increasing demand from Asia Pacific and North America. Continuous revamping of infrastructure in disaster prone countries like Japan is also expected to be a driver for growth after the pandemic.

Request Sample: https://www.chemanalyst.com/ChemAnalyst/RequestForm

Regionally, Asia Pacific dominates the Global polymer concrete market and holds the largest market share in FY20. Asia’s polymer concrete market is anticipated to grow in the economies like India, China, and Japan due to continuously rising urbanization and high demand for environment and chemical resistant construction materials. In South Asia, particularly India, seems to be the key market for polymer concrete as the country is seen as a generally under-supplied market with limited domestic manufacturing. Moreover, increasing focus of the Indian government towards modern infrastructure development through government initiatives like Smart City programme is also an influencing factor increasing the demand of polymer concrete in Asia Pacific and particularly in South Asia.

Major Players:

- Aco Funki A/S

- ULMA Architectural Solutions,

- Arizona Polymer Flooring Inc.,

- TPP Manufacturing SDN BHD,

- BASF SE,

- Polycare,

- Dudick Inc.,

- Metro Cast Corporation,

- Forte Composites Inc.,

- Kwik Bond Polymers,

- Interplastic Corporation.

“Being linked to the high performance materials industry, the global polymer concrete industry has shown a robust growth alongside growing population and changing consumer preference. China serves as the key growth region with sufficiently installed capacities. India also shows an optimistic trend in demand rise during the forecast period as the government is supporting the modern infrastructure development in its Smart Cities programme. Global polymer concrete pricing curve shows strong movement in line with the polymers such as epoxy, vinyl ester, polyester, methyl methacrylate, and others. This coupled with higher processing costs of polymer concrete is going to keep the prices high as compared to other conventional concrete. This might pose a challenge for demand during the forecast period. With new competitors emerging across the Asian polymer concrete market, players anticipate that there will be sufficient supply demand gaps in future. At this, it is extremely important to keep an eye which region will grab the biggest market share in the upcoming years.” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm promoting ChemAnalyst.

|

Attribute |

Details |

|

Growth Rate |

CAGR of 6.54% from 2021 to 2030 |

|

Base year for estimation |

2020 |

|

Historic Data |

2015 – 2019 |

|

Forecast period |

2022 – 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2021 to 2030 |

|

Report coverage |

Revenue forecast, demand & supply, competitive analysis, competitive landscape, growth factors, and trends |

|

Segments covered |

By Application (Asphalt Pavement, Building and Maintenance, Industrial Tanks, Drainage Systems, and Others.) By Type (Epoxy, Vinyl Ester, Polyester, Methyl Methacrylate, and Others.) By Sales Channel (Direct Company Sale, Direct Import, Distributors & Traders, Retailers.) |

|

Regional scope |

North America; Europe; Asia Pacific; South America; Middle East & Africa |

|

Country scope |

United States; Mexico; Canada; China; India; Japan; South Korea; Taiwan; Singapore; Germany; Belgium; France; United Kingdom; Spain; Italy; Sweden; Austria; Saudi Arabia; Iran; South Africa; Brazil; Argentina |

|

Key companies profiled |

Aco Funki A/S, ULMA Architectural Solutions, Arizona Polymer Flooring Inc., TPP Manufacturing SDN BHD, BASF SE, Polycare, Dudick Inc., Metro Cast Corporation, Forte Composites Inc., Kwik Bond Polymers, Interplastic Corporation. |

|

Customization scope |

Free report customization with purchase. Addition or alteration to country, regional & segment scope. |

|

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs. Explore purchase options |

ChemAnalyst is a ‘one stop’ digital platform that offers comprehensive market intelligence data and in-depth analysis of the Indian chemical and petrochemical industry. ChemAnalyst’s team of 100+ analysts are engaged in tracking chemical prices daily, production capacity, demand and supply outlook, manufacturing plant locations, foreign trade data and news/deals for more than 400 major chemicals produced in India. ChemAnalyst is promoted by TechSci Research which is an award winning research based management consulting firm providing market research and advisory solutions to the customers worldwide, spanning a range of industries including Chemicals & Material, Automotive, Consumer & Retail, ICT, Energy & Power, Aerospace & Defense, Water and Waste Management, BFSI and more.

Contact Us:

Nilesh Vishwakarma

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523948

Mob: +91-8882336899

Email: sales@chemanalyst.com

Website: https://www.chemanalyst.com/