According to ChemAnalyst “Caprolactam Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-Use, Sales Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030” Caprolactam market has shown significant growth as its demand reached 7.5 million tonnes in 2021 and is anticipated to grow at a healthy CAGR of 6.85% in the forecast period until 2030. The growing demand for Caprolactam from various end-use industries, including textile, automotive, and construction sector, is expected to boost the demand for Caprolactam market in the upcoming years. Nylon 6 has excellent strength and elasticity, and offers chemical resistance, damage resistance from oils and abrasion resistance. Because of above mentioned properties, it finds application in textile industry and accounts for over 97% of the total Caprolactam; thereby, fueling the Caprolactam market, globally.

Read Full Report Here @ https://www.chemanalyst.com/industry-report/caprolactam-market-100

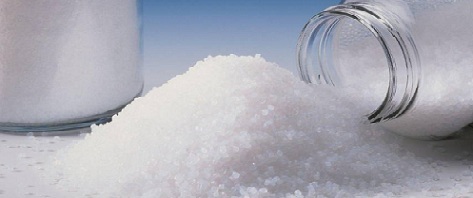

Caprolactam is an organic complex with the chemical formula (CH2)5C(O)NH, having elements such as Carbon, Nitrogen, Hydrogen and Oxygen. Cyclohexane, Ammonia, and Phenol are the raw materials used in production of Caprolactam. Caprolactam is a white‚ hygroscopic‚ crystalline solid with a specific odor. It is basically a cyclic amide of Caproic Acid. Based on the application, Caprolactam is used in the manufacturing of polycaprolactam in the production of synthetic fibres, namely Kaplon, which accounts for roughly 90% of its major usage, the other 10% finds its application in the manufacture of gears, bearings, pipe, medical equipment and electrical, and insulating materials, among others. Caprolactam is used in coatings, plastics and for the synthesis of lysine in a small amount and it is also used as a polymer solvent in the manufacturing of polyamide-synthetic fibres, and chromatography.

In an industrial set-up, Caprolactam is produced by oxidizing cyclohexane, or from phenol or toluene followed by hydrogenation in the presence of sulfuric acid. Produced Hydroxylamine Sulfate in the previous reaction is then reacted with the Cyclohexanone to produce cyclohexanone oxime. In the first stage, Cyclohexanol is formed with combined reaction of Phenol and Hydrogen at 180 degree Celsius in the presence of a Nickel catalyst. In the presence of Oleum, the oxime undergoes the process known as the Beckmann rearrangement to yield the crude Caprolactam. Other methods to produce Caprolactam include the depolymerization of waste Nylon 6, and the reaction of Caprolactone with Ammonia.

Read Free Sample Report Online @ https://www.chemanalyst.com/ChemAnalyst/RequestForm

Caprolactam market is segmented based on end-use, sales channel, and region. Based on various end-uses, the market is segregated into textile, automotive, electrical and electronics and others. Caprolactam is mainly used to produce Nylon 6 fibres and engineering plastics, around 68% of global demand is in Nylon fibre with 32% in engineering resins and films.

The coronavirus pandemic has slowed the global textile industry’s growth, which had a detrimental influence on the economy. To prevent the virus from spreading further due to public gatherings, the government required shop and factories to close. Furthermore, supply chain problems hampered the supply for the product in a number of nations. COVID-19 had an impact on nearly every industry, and its long-term consequences are expected to have an impact on upstream industries and downstream of Caprolactam market growth over the forecast period.

Among different regions, Asia-Pacific dominated the market across the world, with the largest consumption of Caprolactam coming from countries, such as China and South Korea. APAC accounted for the largest share in the Caprolactam market in 2021 and is anticipated to maintain its dominance in the forecast period as well. This has led to increased Polyamide 6 demand in the region, which, in turn, is driving the Nylon 6 and engineering plastics segment.

“Caprolactam Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-Use, Sales Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030” Major players operating in the Caprolactam market include Sinopec Shijiazhuag Refining and Petrochemical Company, China Petrochemical Development Corporation (CPDC), Shangdong Haili Chemical Industry Co. Ltd, Fibrant, Ube Industries, Toray Industries, Sumitomo Chemical Corporations, Honeywell International Corporation, Lanxess AG ,Royal DSM N.V., etc.

“Continuously increasing demand for Caprolactam from several end-use industries including engineering plastics, automotive, fibres and others is projected to boost the Caprolactam market in the span of the next ten years. Ongoing trend of lightweight vehicles and strong structures in automotive industry is another reason for the growing demand of Caprolactam.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

Browse Related Reports

United States Phenol Market Analysis, Plant Capacity, Production, Operating Efficiency, Technology, Demand & Supply, End User Industries, Distribution Channel, Region-Wise Demand, Import & Export, 2015-2030

https://www.chemanalyst.com/industry-report/usa-phenol-market-107

China Phenol Market Analysis Plant Capacity, Production, Operating Efficiency, Technology, Demand & Supply, End User Industries, Distribution Channel, Region-Wise Demand, Import & Export, 2015-2030

https://www.chemanalyst.com/industry-report/china-phenol-market-113

About Us

ChemAnalyst is a leading provider of chemical commodity prices in more than 12 countries from last 4 Years. The company has emerged as a preferred pricing supplier amongst Procurement Managers and Strategy Professionals globally who wants to track near real time prices of chemicals on its interactive dashboard. Unlike most of its competitors such as ICIS, IHS & S&P Platts the company doesn’t believe in delivering prices in PDF reports. The company has developed proprietary algorithm based online subscription platform in which users can track years of historical prices of more than 250 chemical commodities. In addition, since it’s all online, the users cannot just compare prices across multiple countries but also with other commodities and play with the data by generating multiple graphs to find out amazing insights. The users get access to grade wise CIF, CFR & Ex Works prices at multiple ports in each country.

ChemAnalyst also provides market analysis for more than 1000+ chemical commodities such as Production, Demand, Supply, Plant Operating Rate, Imports, Exports, Suppliers, Customers and much more. The company has created online interactive dashboard in which customers can access all this data instantly with a click of a button. The users will not only be able to analyse historical data for past years but will also get to analyse short term and long-term forecasts for coming years. With the access to local field teams, the company can provide high quality reliable market analysis data for more than 20 countries.

ChemAnalyst is a one stop solution for all the data related needs. We at ChemAnalyst are committed to assist customers worldwide with their data and insights needs using our comprehensive online platform.

For more information, please visit us at www.chemanalyst.com

Contact Us:

Nilesh Vishwakarma

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523948

Mob: +91-8882336899

Email: info@chemanalyst.com